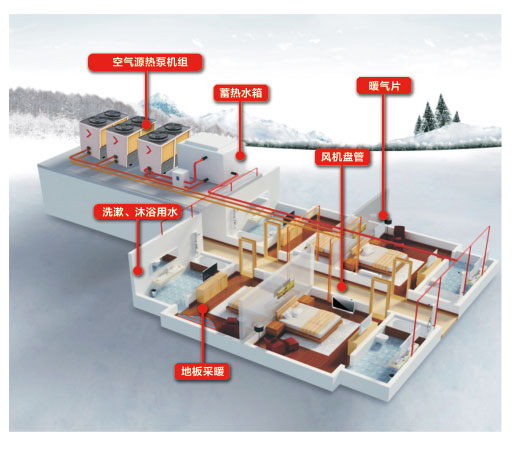

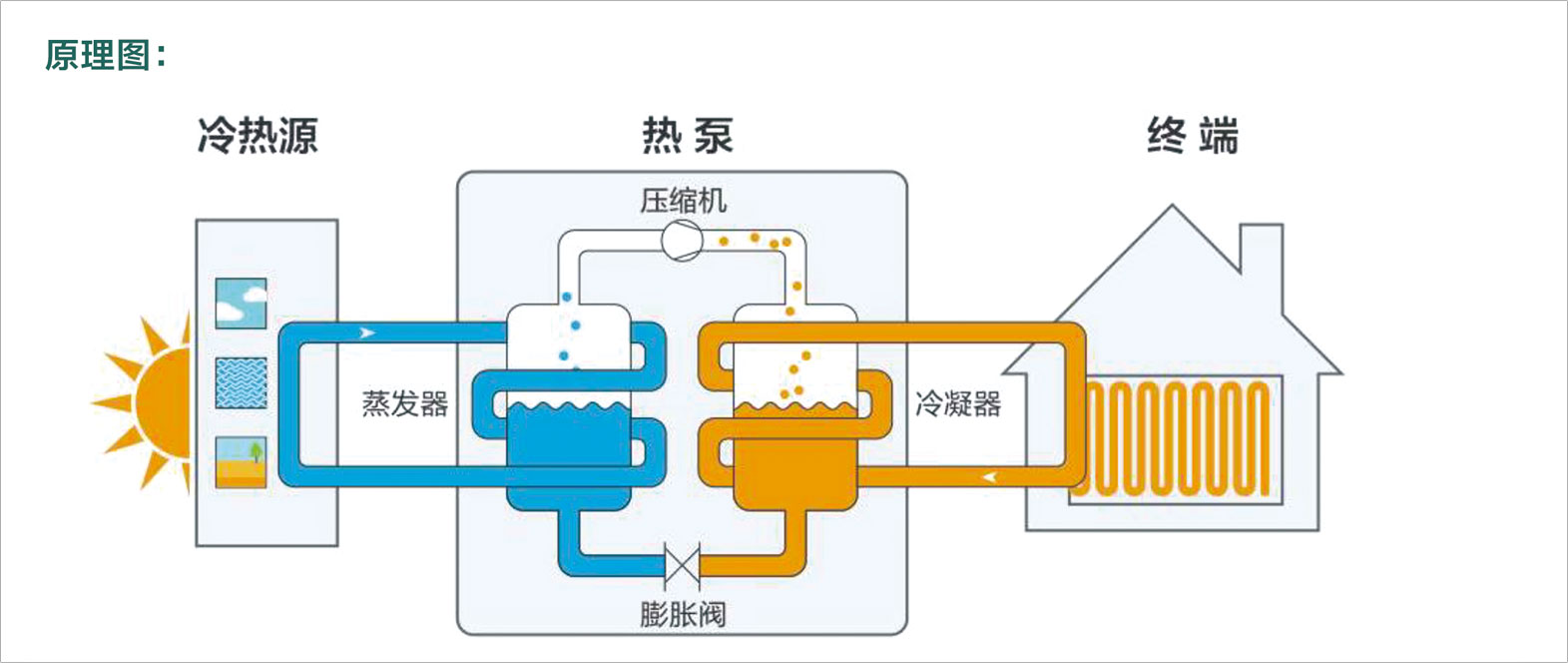

It can carry out normal operation in the low temperature environment, and meet the demand of heating, refrigeration and domestic hot water.

1. Technical optimization of refrigeration system;

2. The water supply temperature in winter is automatically adjusted with the ambient temperature;

3. The unit can be composed of multiple modules to realize parameter setting and other functions through the unit control system;

4. Double working condition unit operation mode renders the unit more energy-saving;

5. Low-temperature modular unit uses environmentally friendly refrigerant R410A

6. The remote monitoring of the cloud platform greatly facilitates mobile terminal access and operational data analysis.

(Water, heating system under-pressure and overpressure protection)

◆Switching between refrigeration and heating modes

◆Timing switch function

◆Controlling pump start or stop

◆Energy regulation, compressor shift function

◆Power-down memory function

◆Intelligent defrost (automatic/manual) control

◆ Self-trouble-shooting function

◆Automatic antifreeze function

◆Remote switch function

◆Group control on temporary combination

◆High and low voltage protection

◆Compressor and fan overload protection

◆Power supply reverse polarity protection

◆Anti frost

◆Exhaust temperature protection

◆Compressor overheat protection

◆Water cut-off protection

◆Inlet and outlet water temperature difference protection

◆Sensor failure protection

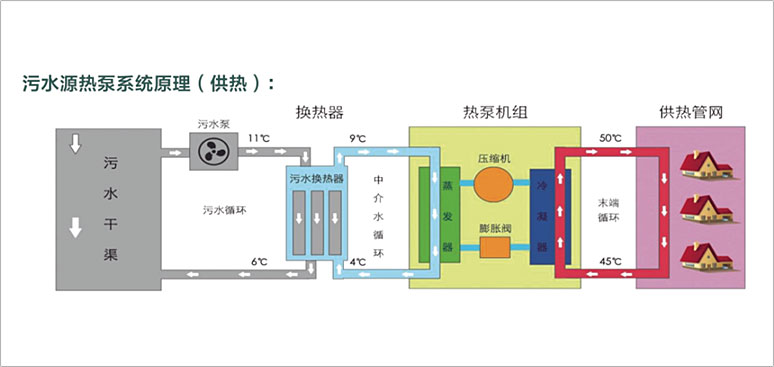

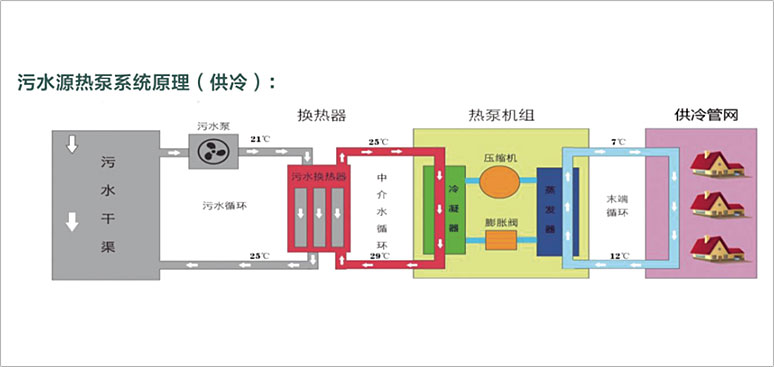

Urban sewage (warm spring water) is mainly used as the cold and heat source, in which the energy is extracted or stored. The sewage source heat pump compressor system, consuming a small amount of electric energy, in winter, the low-grade heat energy stored in water is "extracted" to provide heat for users; in summer, the indoor heat is "extracted" and released into the water, so as to reduce the room temperature, which achieve the purpose of high efficiency, environmental protection and energy saving.

◆Remarkable environmental protection benefits;

◆High efficiency and energy saving;

◆stable and reliable operation;

◆One system serving for multi-purpose and with wide application scope

◆Extracting heat energy from waste water to convert low-grade heat energy into high-grade heat energy, Saving Energy and electricity;

◆No pollution, no emission, no heat island effect.

1. International well-known brand, well-made;

2. Optimized system design, stable and reliable operation;

3. Multiple technical improvements lead to higher efficiency

4. Full Chinese screen, simple interface, flexible operation, one-button boot;

5.Fuzzy control closer to the actual operation mode, making the target more accurate;

6.Choosing the environmentally friendly refrigerant to save energy and protect environment.

The control system adopts humanized touch screen operation and color image display control center, which can monitor the operation status of the unit at any time, provide monitoring, fault recording, safety protection and convenient operation for the unit. Several dedicated contacts and backup contacts are reserved in the control box for users to access the remotely transmit line, remote control alarm line and other control lines.

In the operation mode of the unit, the cooling water outlet temperature of the unit changes with the change of unit load and unit water flow. The unit monitors the difference between the cooling water outlet temperature and the set temperature in real time, automatically adjusts the load of the unit to reach the set temperature of the unit. When a fault occurs during the operation of the unit, the unit displays a fault alarm showing the alarm location and alarm time, and takes protective measures such as fault operation and fault shutdown according to the fault level respectively.

The microcomputer control system is equipped with frequent compressor start and stop protection to prevent the unit from frequent loading and unloading, compressor discharge over-temperature protection, compressor overload protection, high and low pressure protection and other parameters and function control. Upon the main power supply is connected, the control system starts to work and continuously monitors various unit parameters.

◆Work mode display

◆Control mode display (near end control / remote control / automatic / monitoring)

◆Compressor discharge temperature, evaporation temperature

◆Inlet / outlet temperature of evaporator

◆Inlet / outlet temperature of condenser

◆Accumulated start and stop times of compressor

◆Accumulated operation time of water pump

◆Accumulated running time of compressor

◆Working state of input and output points of controller

◆Fault alarm display (location, time)

◆High and low pressure protection

◆Compressor overload protection

◆Phase-change and phase-out protection

◆Oil level protection

◆Compressor internal protection

◆Compressor discharge overheat protection

◆Protection of over low outlet water temperature of evaporator

◆Protection of high / low outlet water temperature of condenser

◆Protection of water flow in evaporator and condenser

◆Compressor start and stop frequent protection

◆Remote switch on / off (passive signal)

◆Timing switch on / off

◆Remote monitoring function

(Reserved RS485 communication interface, can access Modbus RTU open protocol)

◆Power-down memory control

◆Parameter overrun setting limit function

◆Fuzzy energy regulation

◆Antifreeze protection in winter

◆Multiple password setting protection control

◆joint control with side water pump (passive signal)

◆joint control with water/ground source side pump (passive signal)

Address: No. 666 Xinshuini Road, Ganjingzi

District, Dalian, Liaoning Province

Telephone: 0411-66880585/66880562

Fax: 0411-66880585

E-mail: hd_dl@163.com

The company continues to create high quality products,

to provide customers with energy saving, environmental

protection, perfect cooling and heating solutions.

The products of Dalian Hongding are highly efficient and

easy to use and maintain, achieving energy conservation

and emission reduction, reducing costs and increasing

economic benefits for enterprises.

“Good Faith, Quality

First, Brand Establishment, Widely Renowned” is the object

of the company.